We’re your partner for premium print quality. Allow us to show you around.

The Kaufmann name has represented maximum levels of print quality over six generations. We offer our customers a product portfolio that meets the needs of the market; and we design work processes with maximum simplicity and efficiency. As an expert partner uniting fully integrated prepress, sheet-fed and web offset printing, post-processing and shipping under one roof, we support you across the complete production process with high-quality print media.

We invite you to get to know our range of services with a tour through our printing house – simply take a look around.

SandyProfessional

Climate-neutral printing

Tour

- Project management.

- PrePress.

- Technology.

- Print is impressive.

- Quality management.

- Post-processing.

- Adhesive binding.

- Lettershop.

- International shipping.

- Feedback.

At Druckhaus Kaufmann, a personal contact person is available for the complete realisation of your print project – and if requested including individual shipment.

In prepress, supplied electronic print data is checked and the printing plates are created. Our media designers monitor and control this work process.

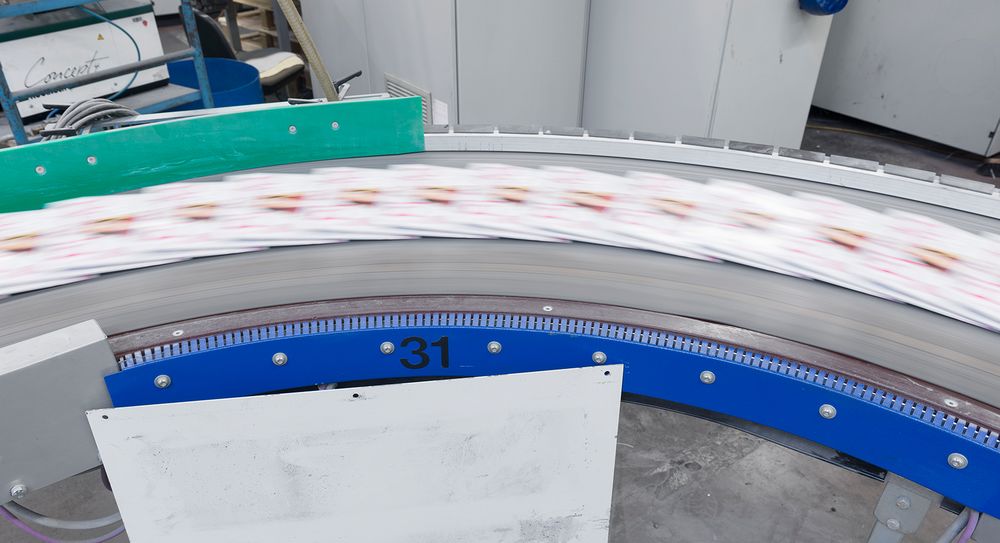

We work with the latest prepress methods, web and sheet-fed offset printing machines from leading manufacturers and state-of-the-art post-processing technology.

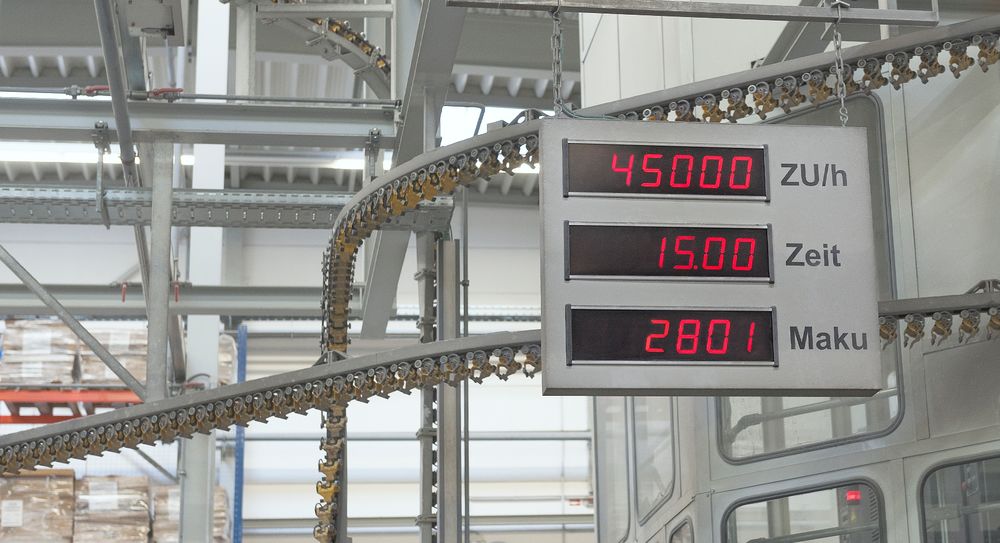

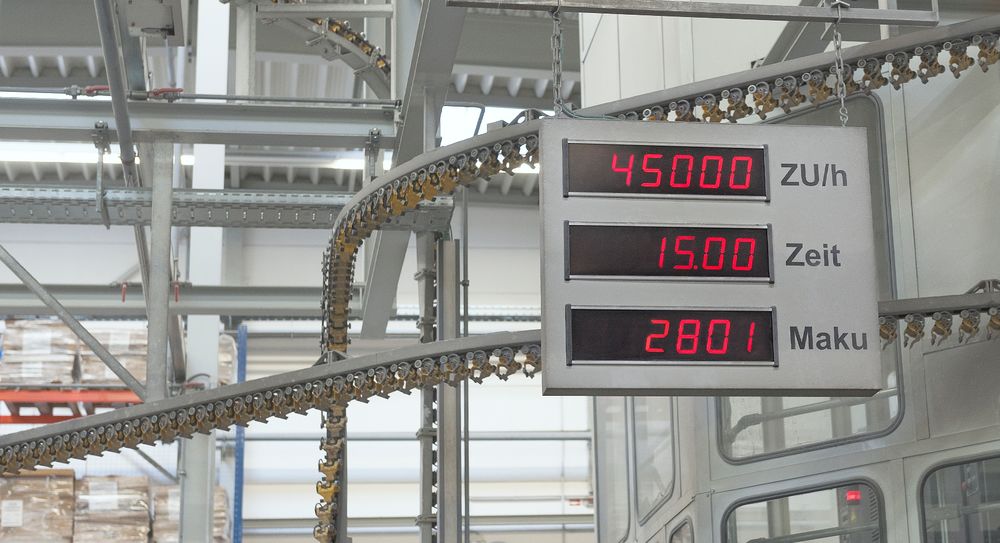

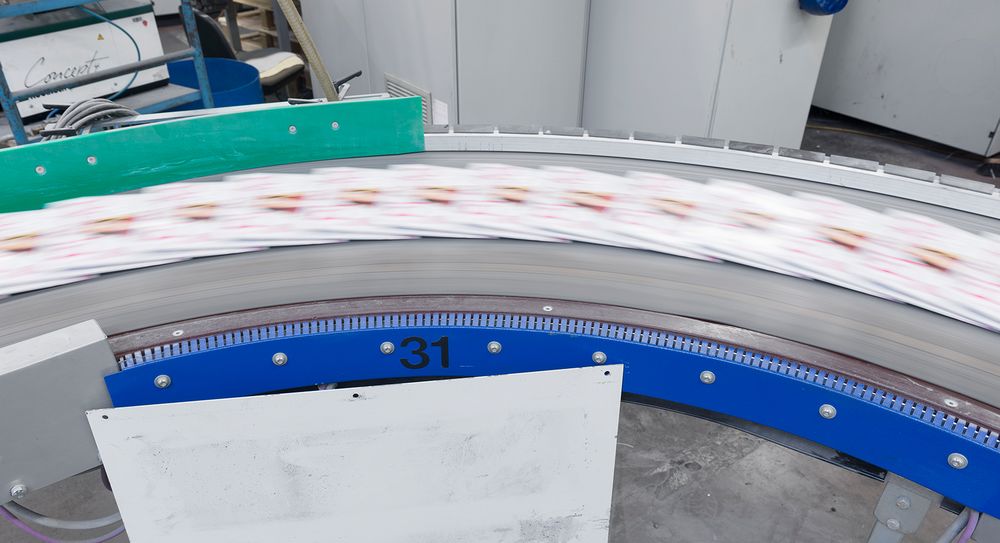

Up to 50.000 sheets can be printed per hour in 4/4 and maximally in 5/5-colour on printing machines with lengths up to 50 meters.

As part of our certified quality management, a quality check is carried out after each work step. This leads to optimum Kaufmann quality.

In post-processing, the print sheets are folded, stapled and adhesive-bound to produce the final product in top quality.

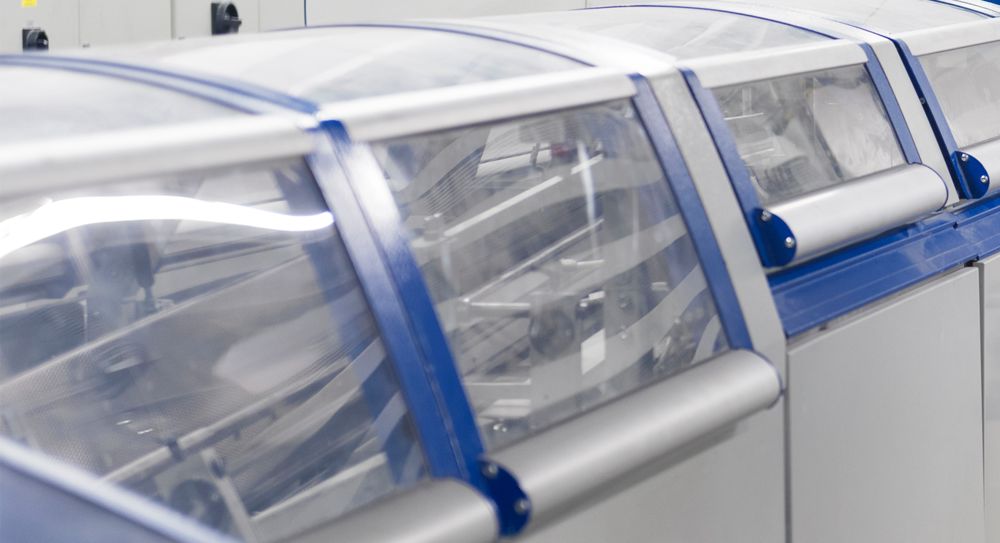

Our state-of-the-art, high-performance adhesive binders ideally bring together what belongs together. This creates long-lasting bonds, and with our customers as well.

This is where the printed products are labelled with the relevant shipping details. Names, addresses and supplementary postal information can be applied to catalogues.

Of course, we also take on deadline-compliant shipping to countries around the globe. From scheduling of packages and customs clearance of orders to invoice control and freight shipments, our work is only done when you have reached your customers.

Mission accomplished, please reply. We ask our customers whether the quality of our print products and services was convincing, and your feedback helps us to fine-tune our work.

At Druckhaus Kaufmann, a personal contact person is available for the complete realisation of your print project – and if requested including individual shipment.

In prepress, supplied electronic print data is checked and the printing plates are created. Our media designers monitor and control this work process.

We work with the latest prepress methods, web and sheet-fed offset printing machines from leading manufacturers and state-of-the-art post-processing technology.

Up to 50.000 sheets can be printed per hour in 4/4 and maximally in 5/5-colour on printing machines with lengths up to 50 meters.

As part of our certified quality management, a quality check is carried out after each work step. This leads to optimum Kaufmann quality.

In post-processing, the print sheets are folded, stapled and adhesive-bound to produce the final product in top quality.

Our state-of-the-art, high-performance adhesive binders ideally bring together what belongs together. This creates long-lasting bonds, and with our customers as well.

This is where the printed products are labelled with the relevant shipping details. Names, addresses and supplementary postal information can be applied to catalogues.

Of course, we also take on deadline-compliant shipping to countries around the globe. From scheduling of packages and customs clearance of orders to invoice control and freight shipments, our work is only done when you have reached your customers.

Mission accomplished, please reply. We ask our customers whether the quality of our print products and services was convincing, and your feedback helps us to fine-tune our work.

SandyProfessional. Advantage via screen technology.

During printing, text, images and diagrams are screened in order to reproduce various grey scales and colour tones. Photos gain even better brightness and depth characteristics with the innovative SandyProfessional screen technology, leading to significantly calmer, optimum image reproduction and improving overall printing results – with our Sandy, the screen dots are not adjacent but form a fine network, meaning the eye perceives a perfectly crisp printed image. It’s the fine differences that visibly improve the quality of printed products.

We are also pleased to offer you less: less CO₂ emissions thanks to climate-neutral printing.

An increasing level of environmental awareness means that ever more companies take the decision for climate-neutral printing of their print products. This in turn means that all CO2 emissions generated from production to the shipment of printing products are compensated for by supporting internationally accredited environmental protection projects. Together with ClimatePartner, we enable verifiably climate-neutral printing in accordance with the gold standard certificate. The specific naming of the supported environment protection project emphasises the level of responsibility that your company is taking on – certified excellence for our climate and your reputation.